More About 24??media

More About 24??media

Blog Article

How 24??media can Save You Time, Stress, and Money.

Table of ContentsThe Single Strategy To Use For 24??mediaThe Buzz on 24??media3 Simple Techniques For 24??media24??media for BeginnersSome Known Details About 24??media

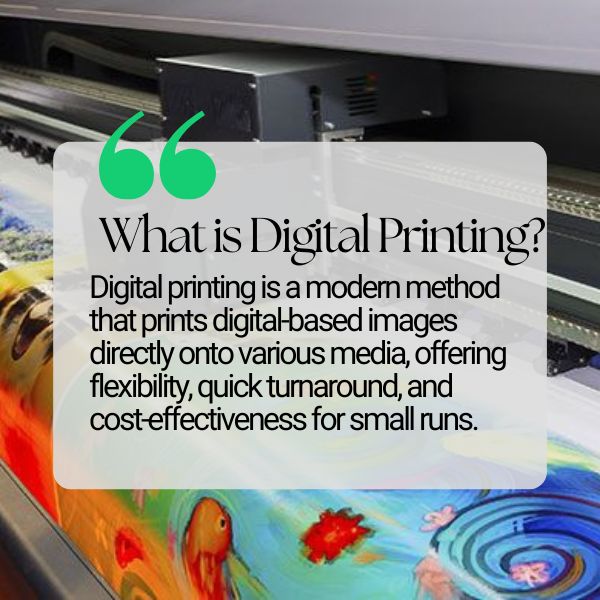

Innovations in print technology are transforming the communications playing field when it involves quality, affordability and sophisticated capacities. Offset printing and electronic printing are the major procedures by which print work are embarked on both utilizing four-color printing techniques. Each choice has its advantages, providing various strategies to fulfill the requirements of diverse manufacturing projects.

Typically, this has actually been the most regular method for precisely keeping shade suits, making it suitable for print runs that just call for fixed printing such as pre-printed forms, sales brochures, flyers, calling card, and bulk postcard mailings. Nevertheless, as a result of the fixed nature of litho printing, it is not optimal for variable print items that will be sent by mail to individual recipients such as statements, letters, and customized postcards.

Excitement About 24??media

The latest developments in print innovation are helping to bring many of balanced out's benefits right into the digital printing globe really altering the face of modern printing! There are some key differences between Offset Printing and Digital Printing.

Today's electronic print devices is among one of the most innovative on the market. Below are several of the largest benefits of using digital printing: control the electronic print area, with full-color printing completed in one procedure and seamlessly published directly from a print file. Without a prolonged set-up process, the calibration time of a particular job is shortened, contributing to quicker print time and general distribution.

The inkjet printing process has actually aided to change the industry as well as the quality and rate of the outcome. The most up to date inkjet technology can publish on standard balanced out supplies with boring, silk, and glossy surfaces. Top notch digital print paired with software-managed color management techniques adds optimum value to publish pieces and makes production procedures much more reputable than balanced out.

24??media Fundamentals Explained

(https://www.dreamstime.com/fredmack01_info)

Environment-friendly and naturally degradable inks and printer toners are also offered for more sustainable printing. Digital print additionally removes the demand to wash plates or blankets with damaging chemicals at the end of the printing procedure.

Variable data aids businesses reach their exact clients and target market with uniquely-created and individualized content. As technology enhances, the high quality of electronic printing has ended up being second-to-none, with greater detail, shade match capacities and general accuracy. Without the demand to clean plates or use excess ink, electronic printing is also less wasteful and typically a lot more ecologically pleasant.

Conventional printing approaches, such as balanced out lithography ("offset") and flexography ("flexo"), include numerous make-ready actions to move an initial picture to a substrate. These methods call for the manufacturing of a collection of plates placed on a cylinder to move ink that forms the wanted photo when integrated on paperboard and various other product packaging materials. Large Format Printing.

24??media for Dummies

While electronic printing is a practical choice for most short-run print tasksspecial celebrations, prototyping, or various other considerationsits modern capacities truly show in quick turn-arounds. Being able to personalize packaging through variable information printing has opened brand-new possibilities for you to involve with your customers in more individualized means. Digital printing, with less moving items, is extra dexterous than offset hereof.

It's a way to mix your this article packaging and marketing techniques. Minimized set-up time saves money on the front end. And because these are not massive mass orders, smaller companies can manage to print without having to fulfill the higher and much more pricey print limits of conventional printing. Digital printing aids safeguard your brand name versus counterfeiting by integrating overt and covert solutions on your product packaging.

Be sure you collaborate with a printing and product packaging companion that has the ideal qualifications. While eleventh-hour printing and customization are a massive advantage, electronic may not constantly be the most effective technique for you. Balance out printing has the advantage of cost-effectiveness with large print runs, especially those with innovative attractive results and specialty coverings.

24??media Can Be Fun For Anyone

Lithographic presses utilize 2 print platesa positive and a negativeto transfer premium color graphics onto an ideal substratum. The favorable plate, with its smooth surface area, attracts oil-based inks and drives away water. In comparison, the negative plate, with its harsh appearance, absorbs water and fends off oil. Rubber rollers are after that made use of to transfer the image from the plate to the corrugated surface.

Corrugated paper can occasionally confirm to be a difficult surface to print on, but Litho prints to a separate surface area and is then laminated flooring to it, making it easy to print high-quality pictures. It can be extremely constant, also for futures. The more you print, the less expensive the prices end up being for Litho.

What Litho does not offer you is precisely what Digital does, customization. Costly set up Longer turnaround No Variable Information Printing Smaller sized color range, colors can be much less brilliant Digital printing is the process of printing digital photos directly onto the corrugated substrate using a single-pass, direct-to-corrugate technique.

Report this page